Hot dip simulators – well galvanized against corroding rust

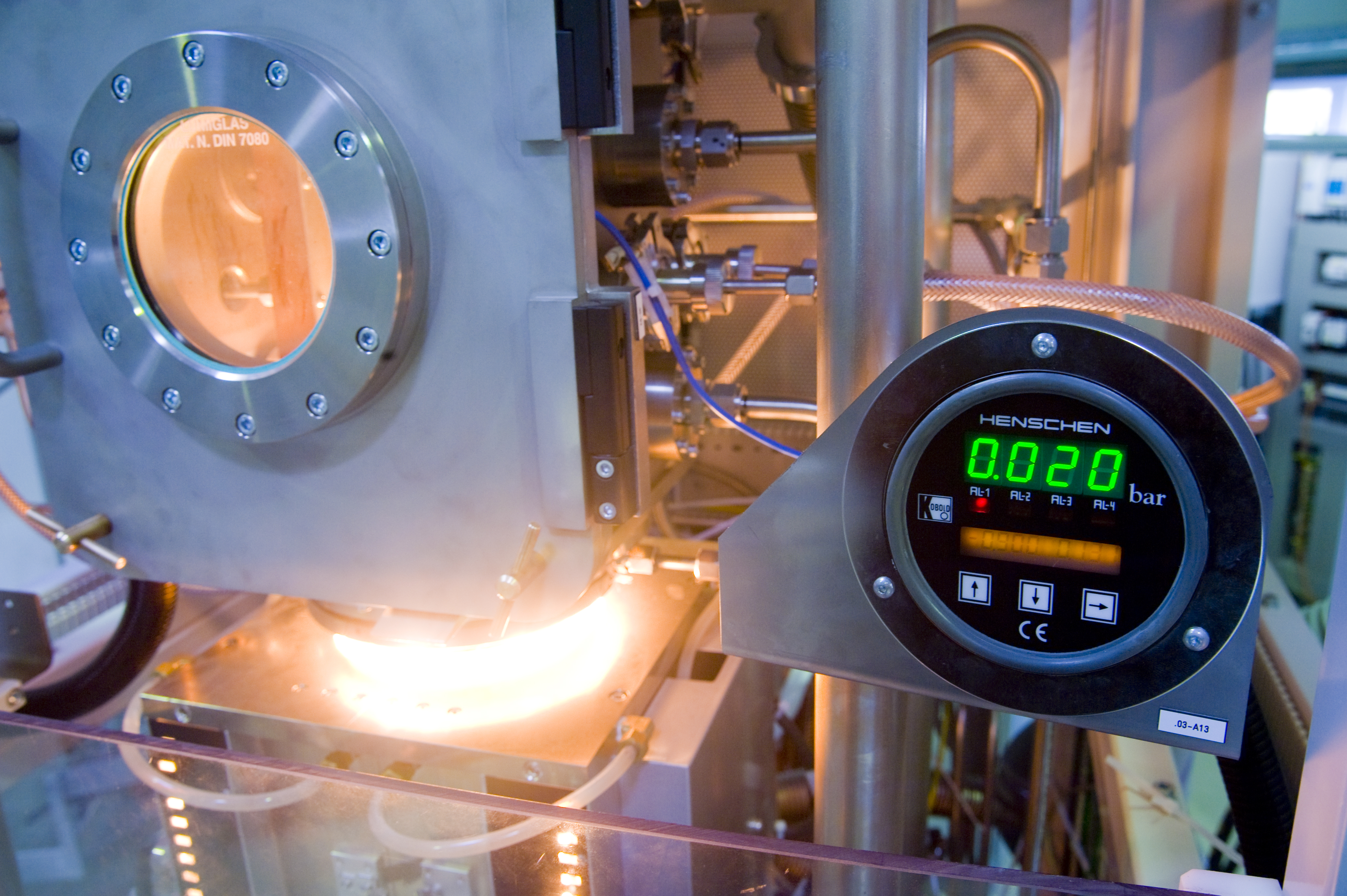

Nowadays, galvanized steel is manufactured using different processes, depending on the type of material. Steel strips are fed through continuous strip galvanizing plants, for example. The individual handling processes are hereby the result of elaborate laboratory tests. In order to accelerate the work which is entailed in the development of new processes, steelworks and research institutes use hot dip simulators from the Dusseldorf company Iwatani GmbH. Having been constructed for research and development, the plant can be used later in order to exactly reproduce production processes at a later date.

This approach faces the engineering specialists from Falk Steuerungssysteme GmbH with motive power engineering challenges in order to reproduce the continuous passage of the zinc bath by means of a melt process. The longer the metal sheet remains in the melt, the thicker the coating. If the sample passes into the molten metal via a combination of a servomotor and recirculating ball screw, i.e. comparatively slowly, the lower regions have a much denser zinc layer, when compared to the higher regions. This so-called Christmas tree effect does not occur with galvanized strips as the steel strip runs through the metal bath continuously and is subjected to the same duration.

The solution from Stadthagen: the metal sample which measures approx. 12 x 20 centimetres travels to the end position with the maximum acceleration after it has reached the melt surface. The actual stay duration – normally between one and two seconds – then counts until it leaves again at the same speed. Maximum acceleration rates of 25m/s² are achieved here. The aim of these efforts is to finally reduce the time required for the submersion and emersion to a negligible minimum, when compared to the duration of stay, in order to obtain laboratory results which can be reproduced in real production conditions at a later date.

document download (pdf, german)