Centre section

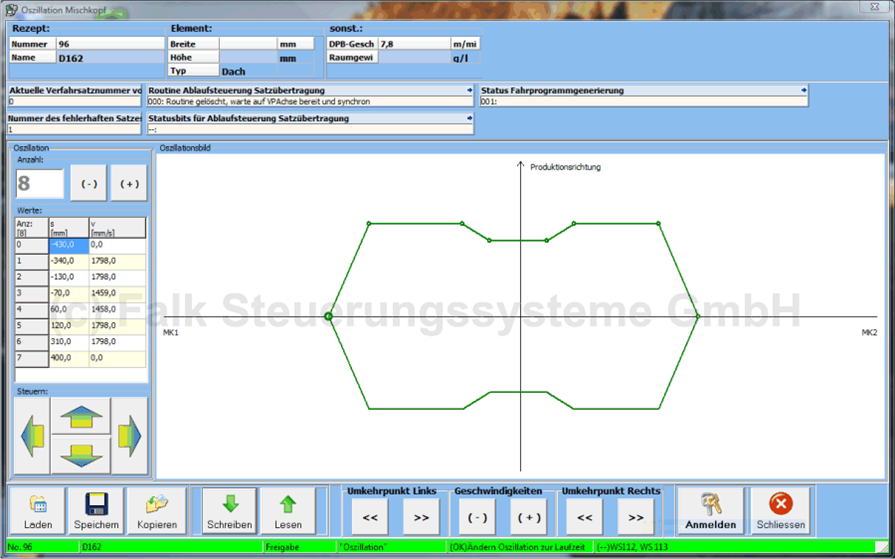

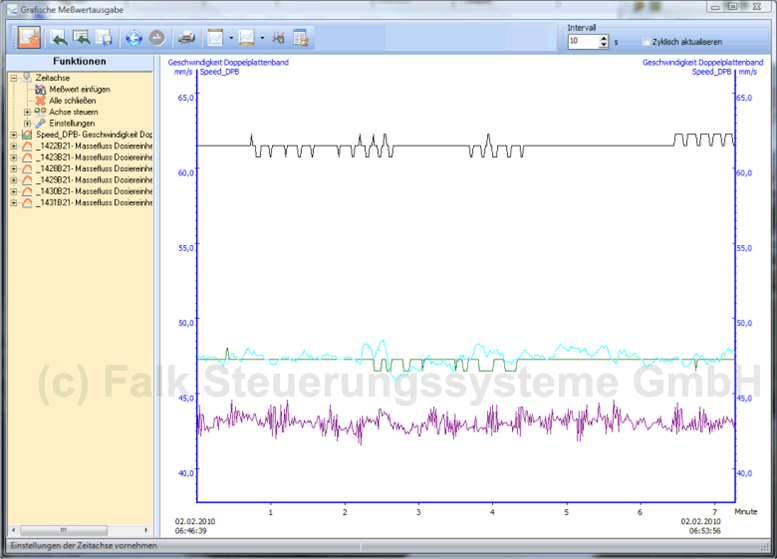

In the centre section the pre-selected foam compound is applied to the bottom band and the bands moved together to form the double board band. The foam is applied using oscillation or statically, the so-called "stationary casting rake". The optimum distribution of the foam on the bottom band is of major importance for the quality of the sandwich panel. For subsequent analysis, e.g., the actual flow rates are measured and saved in the control system in seconds.

Hardware layout:

- Approx. 30 inverter drives

- 1 x SIEMENS-PLC 317-2 DP

- Approx. 200 inputs/outputs

Software:

- Automatic bow wave control

- Automatic sheet metal temperature control

- Foam application by oscillation or statically ("stationary casting rake")

- Automatic metering pump control

- Measurement recording for subsequent analysis in the control system

- Automatic mixing head change without production downtime

- and much more