Control system

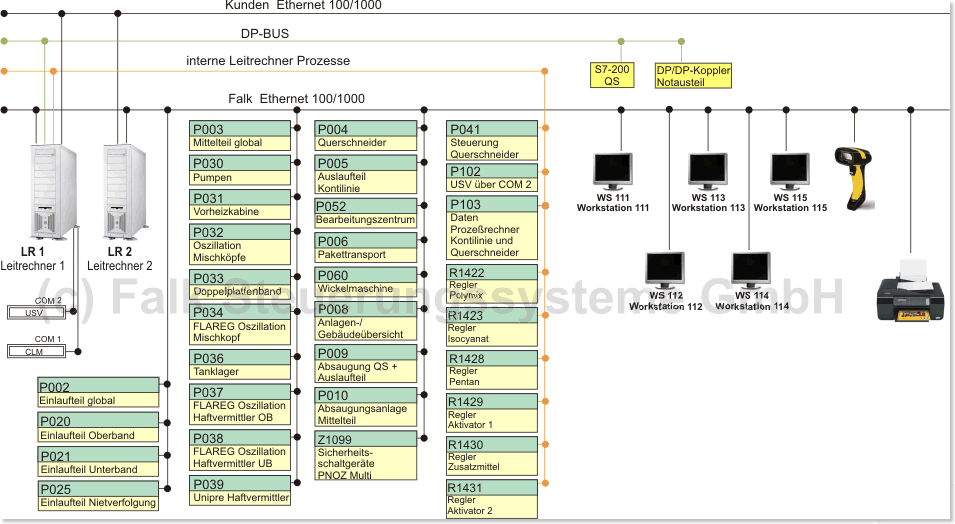

The control system represents the higher level control of the sections of the machine.

All data are entered and managed here. The data are available at any time to authorised users. All data display elements can be seen both on the control computer and also on each workstation. The control computer updates the information in the workstations with efficient, event-controlled communication so that the workstations display the current plant situation in real-time.

Hardware layout:

- 2x Siemens industrial PC -> control computer + replacement control computer

- GigaBit interface to all Ethernet devices

- Communication entirely via Ethernet -> no special boards are required

- As many workstations as required can be integrated

Software:

- Developed in Delphi 2009 for MS Windows 32 / 64 bit

- Communication via OPC, UDP, FDL, DP and serial

- Multi-language support, language can be changed while running (e.g. English, French, Spanish, Hungarian,...)

- Virtualization of the control system and the connected workstations

- UPS integrated in the control system with voltage monitoring of the UPS

- Material tracking and data display in the control system

- Pack parts lists for pallet and polystyrene arrangements in the control system

- Preparation list, cutting list, shift log can be viewed and edited at any workstation

- Display of all measured values in the system

- Display and editing of all machine parameters (setpoints)

- Continuous incremental data backup from the control computer to the replacement control computer

- and much more