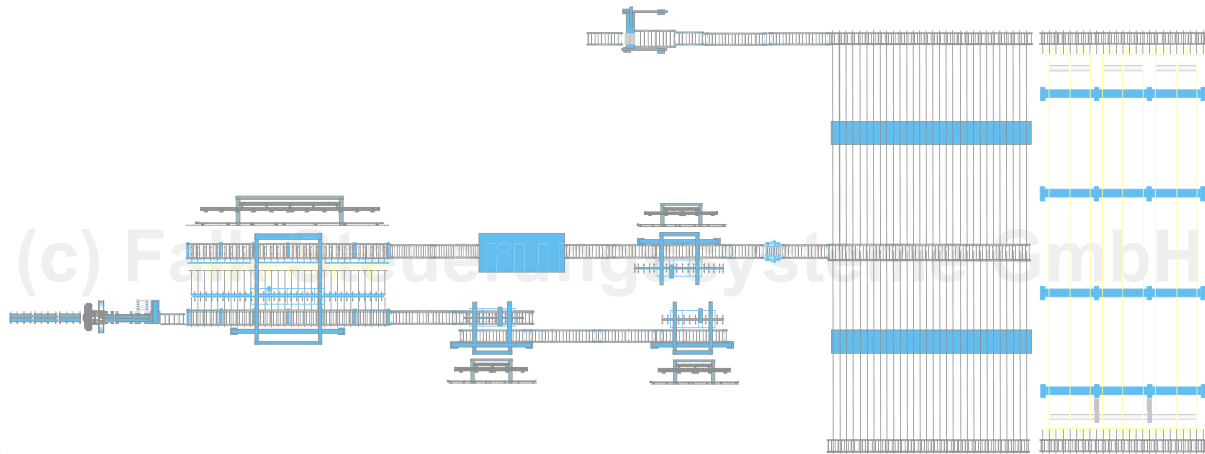

Outfeed section

In the outfeed section the panels are conveyed over various roller tables for further machining and final packaging.

Depending on the type of panel, different further processing is started. The 1A panels are stacked into a pack and

transported on for final packaging.

Hardware layout:

- Approx. 80 inverter drives

- 1 x SIEMENS-PLC 317-2 DP

- Approx. 550 inputs/outputs

Software:

- Reliable step sequence programming

- Material tracking in the control system

- Further processing of the panels (e.g. milling, notching, cold bridge, ...) is saved in the element data in the control system

- Different forms of stacking are possible (e.g. block stack, tree stack, x-times, ...)

- Automatic and semi-automatic pack stacking

- Automatic turning unit for roof elements (up to 5 different turning programs)

- Separate short component line for cutting and forming packs of short components

- and much more