Simulation of hot dipping process for galvanising steel plate

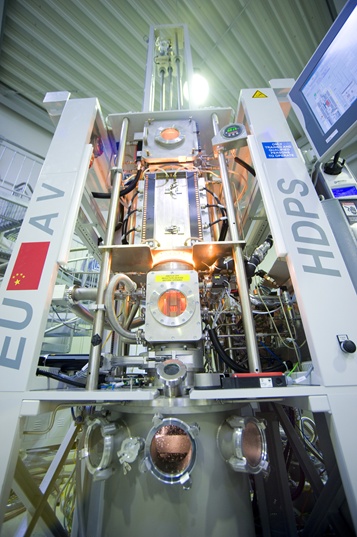

Falk Steuerungssysteme's know-how on the equipping of systems for the simulation of hot dipping process using hardware and software can certainly be termed special. The SURTEC RESEARCH (former Rhesca or Iwatani HDP Simulators) simulator makes it possible to simulate on laboratory scale the industrial production of surface-treated sheet metal (car) parts during galvanising. The main functions of the simulation of the hot dipping process are the thermal treatment in oxidising or reducing atmospheres as well as the actual metal coating (galvanising).

In a so-called hot dipping process the pieces of sheet metal are coated with zinc, aluminium or special alloys. The hot dipping process simulation therefore clears the way for new galvanising processes. Background: galvanised steel is produced today using various processes, depending on the nature of the material. The individual processes are the result of extensive laboratory tests.

To accelerate the development work on new processes and alloys for galvanising, steel works and research institutes use systems for the simulation of the hot dipping process. Built for research and development, these compact solutions can be used to exactly simulate subsequent production processes. In galvanising the simulation of the hot dipping process therefore prevents unpleasant surprises on the switch from the laboratory to large-scale production.