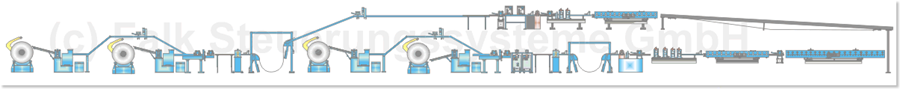

Infeed section

In the infeed section the top and bottom metal covering layers for the sandwich panel are unwound from the coils. The top band and bottom band are then further processed to suit the customer order. There are different types of motive, lines, profiles and many other features.

One form of special processing on the bottom band is, e.g., the stamping of a cassette (sectional door), the bonding of a film (lamination for roof elements) or cutting out certain areas of the metal sheet. The related processes for the top and bottom band are entered in the control system.

Hardware layout:

- • Approx. 80 inverter drives

- 1 x SIEMENS-PLC 317-2 DP

- • Approx. 200 inputs/outputs

Software:

- Automatic positioning of all adjustable axes

- Automatic regulation of length of the loop

- Automatic control of the decoiler

- Automatic joining of the metal sheet by a joining station -> as a result it is not necessary to run the plant empty

- Automatic event control by the control system (e.g. coil change, profiling change, ...)

- Short downtimes due to quick setup of all adjustable axes after the end of the job -> as a result it is possible to continue with the next job without completely emptying the plant

- and much more