Precisely regulated process gases for excellent metal coating

During metal coating, process gases play an important role. In numerous industrial and laboratory applications it is therefore necessary to use a gas flow or air flow with an exactly defined moisture content. Examples are sensor calibration processes, welding processes, clean-room technology, fuel cells or the wide field of metal coating. Water molecules in process gases during metal coating, for instance the annealing of steel surfaces, result in the release of carbon atoms from the metal lattice and their reaction with the oxygen atoms in the water to form carbon monoxide or carbon dioxide. This decarbonisation consequently changes the properties of the material used prior to metal coating.

So that this effect can be utilised specifically in process technology, the moisture content of gas flows must be known. Accordingly, in many cases sensors are used that measure the dew point in a comparatively complex manner. This task is easier with DewCal. A further innovation from Falk is the MS probe. This probe makes it possible to continuously analyse the reactions during metal coating while the process is in progress.

InduSLEEP® - Just switch off

With InduSLEEP® we offer a new way to reduce the energy consumption of your industrial plant. Whether it's an empty shift, a short break or a longer shutdown: InduSLEEP® enables the systems to be safely switched off during any interruption in operation. Maintenance and repairs can therefore be carried out more flexibly and spontaneously.

Mit InduSLEEP® bringen wir ein neues Produkt zum einfachen Ein- und Abschalten Ihrer komplexen Industrieanlage auf den Markt. Egal ob Leerschicht, Pause, Ferien, etc. mit InduSLEEP® lässt sich einfach Energie sparen. InduSLEEP® ist förderfähig über die KfW.

Mit InduSLEEP® bringen wir ein neues Produkt zum einfachen Ein- und Abschalten Ihrer komplexen Industrieanlage auf den Markt. Egal ob Leerschicht, Pause, Ferien, etc. mit InduSLEEP® lässt sich einfach Energie sparen. InduSLEEP® ist förderfähig über die KfW.DewCal® - adjusting and controlling dew points

Using DewCal® dew points of gases can be adjusted and controlled more quickly.

A patent application has been filed for this system, which makes absolute measurements. DewCal® is primarily designed for industrial and laboratory applications that require gas flows or air flows with an exactly defined moisture content.

Read article

Falk Steuerungssysteme GmbH has been registered as the owner of the trademark DEWCAL® with the Deutsche Patent- und Markenamt (German patent and trademark authority).

For more information http://surtec-research.com/

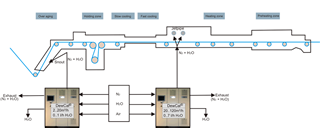

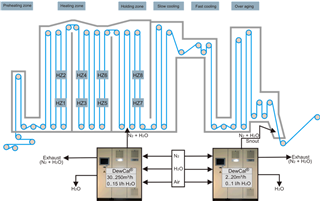

DewCal® for industrial use

Precisely humidified process gases must be used to ensure the quality of galvanization processes with hot-dip coating facilities, and for the generation of defined properties of material.

For this purpose, horizontal and vertical hot-dip coating facilities are operated with Dewcal- systems:

Download "Operating Manual"

Information regarding the gas distribution and motion in the respective furnace chamber is necessary for the precise process-oriented specification of the required amounts of water. Research with argon test gas has been done for this purpose.

Published „Falk et al_Spektrometert-2013-QS-FBA.pdf“ (german)

Distributor: SURTEC RESEARCH (former Rhesca or Iwatani HDP Simulators)

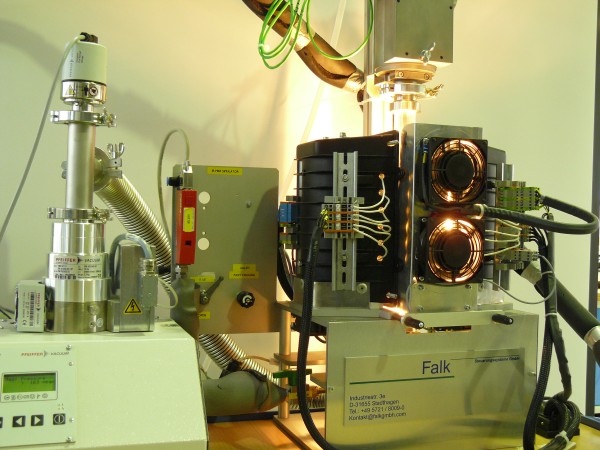

MS Sonde – a thermal reactor with a mass spectrometer probe

Falk Steuerungssysteme GmbH hat developed a new type of thermal reactor with a mass spectrometer connected to it for studying the gas phase reactions that occur during the heat treatment of metals. With the aid of the MS probe, in-situ measurements of the gas phase surrounding metal samples can be made during heat treatment and forming. Continue reading article on MS probe

A patent application has been filed for the MS probe.

See also: 17th Meeting for Applied Optical and X-Ray Spectroscopy in Dortmund